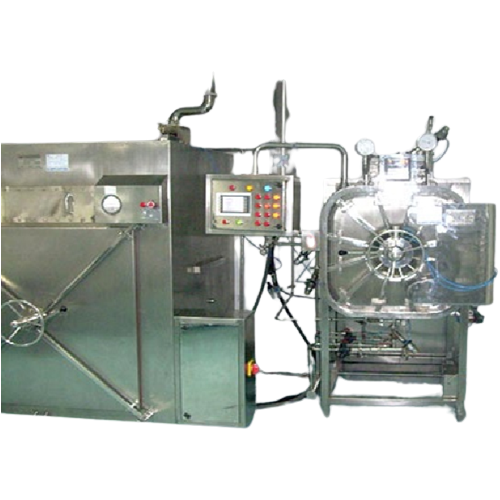

Pharmachem Cosmetics Industries, as a leading AutoClave Manufacturers in Mumbai, produces PCI Superheated Water sterilizers capable of conducting counter-pressure sterilization for large-volume parenteral solutions using an advanced superheated water spray system. Steam sterilizers are also recognized by the name autoclaves.

In compliance with cGMP and FDA standards for LVP products, PCI autoclaves are suitable for treating loads in containers that may be deformed due to the difference in pressure between the chamber and the container itself. Autoclave Suppliers in Maharashtra, supply liable products for separation or for accelerating thermal transition phases, the whole load can be rotated during the entire sterilization process. There is minimum involvement of manual labor, simplified maintenance, and utilizing modular construction techniques to provide flexible installation options.

An autoclave is a device that offering by Autoclave Manufacturers and Suppliers in India, that employs steam under pressure to eliminate harmful bacteria, viruses, fungi, and spores from items enclosed within a pressurized vessel. These items undergo heating to achieve an optimal sterilization temperature for a specified duration. The steam's moisture facilitates effective heat transfer, disrupting the protein structure of bacteria and spores. Due to these attributes, it stands out as a prominent exporter in the industry.

Design & Technical Features:-

Compliant to:-

Key Benefits:-

© Copyright 2024 PharmaChem Cosmetics Industries. All Rights Reserved. Website Designed & Promoted by Web Vyapar India.