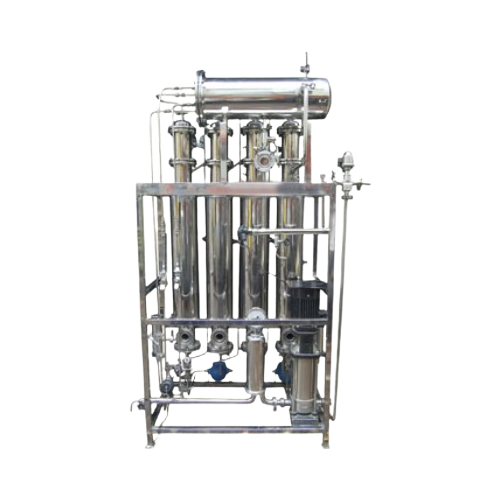

The distillation plant has numerous columns where the process of distillation goes on. The machines from Pharmachem Cosmetics Industries equipment use the Finn-Aqua policy.

Multi Column Distillation Plant Manufacturers in Mumbai, are using principles of interstage heat exchange. These are interstate ethics (multi-effect distillation) to produce pure distilled water that is free from the presence of any progeny. The water thus gained is distilled to such purity standards as have been approved by the IP/BP to be used as injectable.

Industry

In the pharmaceutical industry, the production of pure and sterile water is of extreme importance. The Multi Column Distillation Plant Suppliers in Maharashtra ensures the removal of impurities, such as melted solids, organic compounds, and microorganisms, from the water used for drug invention, injection solutions, and sterile manufacturing procedures. It meets the stringent water-worth values required for pharmaceutical production and ensures the safety and efficacy of pharmaceutical products.

Biotechnology and Life Sciences:-

The Multi Column Distillation Plant Manufacturers and Suppliers in India play a dynamic role in biotechnology and life sciences research and manufacturing methods. It provides high-purity water for several applications, including media preparation, cell culture, DNA sequencing, protein purification, and the invention of sensitive biopharmaceutical products. The plant confirms the elimination of contaminants that could interfere with critical biological processes, maintaining the integrity and reliability of experimental effects and product worth.

Food and Beverage Industry:-

Purified water plays a critical role in the food and beverage industry, serving various purposes like ingredient preparation, beverage production, and equipment cleaning. A multi-column distillation plant is instrumental in eliminating impurities such as minerals, dissolved solids, and potential contaminants. This process ensures the safety and quality of the final food and beverage products, preserving their desired taste, texture, and shelf life

Power Generation:-

In power plants, particularly in steam power generation, high-purity water is needed to avoid corrosion and scaling in the boilers and turbines. A multi-column distillation plant produces demineralized water that meets the stringent desires for power generation. Purified water contributes to optimizing the efficiency and reliability of power plant operations, reducing equipment downtime, and minimizing maintenance costs.

Electronics and Semiconductor Manufacturing:-

The electronics and semiconductor industries need ultrapure water for numerous manufacturing procedures, including wafer cleaning, etching, and photoresist preparation. The multi-column distillation plant produces water with very low levels of impurities, such as ions, particles, and organic compounds, confirming the integrity and yield of semiconductor devices. It helps avoid contamination-related faults and enhances the overall quality of electronic components.

Laboratories and Research Facilities:-

Research laboratories, scientific institutions, and testing facilities frequently demand high-quality water for experimental procedures, analytical equipment, and sample preparation. The multi-column distillation plant ensures a dependable supply of purified water that meets stringent standards for research and analysis. This guarantees accurate and reproducible results, fostering the advancement of scientific knowledge and discoveries.

Features of Multi-Column Distillation Plant:-

Salient Features:-

Technical Specifications:-

| Capacity Supply | Steam | Cooling water | Capacity Supply | Steam Cooling | Cooling water |

|---|---|---|---|---|---|

| 80 | 40 | 120 | 145 | 44 | 180 |

| 150 | 48 | 180 | 285 | 85 | 350 |

| 300 | 97 | 365 | 570 | 170 | 700 |

| 500 | 130 | 605 | 920 | 275 | 1130 |

| 700 | 175 | 860 | 1200 | 360 | 1475 |

| 1000 | 238 | 1265 | 1920 | 575 | 2360 |

| 1500 | 390 | 1700 | 2750 | 825 | 3385 |

| 2000 | 440 | 900 | 3835 | 1150 | 4720 |

| 3000 | 660 | 650 | 5500 | 1650 | 6770 |

| 5000 | 1200 | 1100 | 9585 | 2875 | 11795 |

© Copyright 2024 PharmaChem Cosmetics Industries. All Rights Reserved. Website Designed & Promoted by Web Vyapar India.