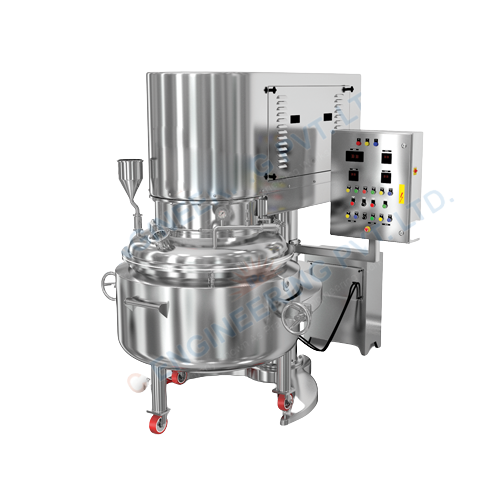

Pharmaceutical Cosmetic Industries stands out as a premier Planetary Mixer Manufacturers in Mumbai. Our equipment is designed for mixing assembly with a planetary agitation pattern. The beater or agitation assembly rotates around itself and travels in a circular motion within the bowl, ensuring thorough and intimate mixing.

We are a leading as top-most supplier Planetary Mixer Suppliers in Maharashtra are renowned for their top-notch service, attributed to the special design feature that ensures uniform and thorough blending of the mass. The unit consists of a Bowl SS Cylindrical bowl with a spherical dished bottom with an inside surface polished to a smooth finish. MS Jacket on cylindrical and spherical area to operate on 3 Kg/cm sq. Steam pressure Complete with steam inlet and cold water inlet and outlet connections with standard fitting like pressure gauge, vent cock, release valve, and drain.

The bowl is also appropriate for vacuum application and fitted with 3 nos. Of the castor wheel, two secure and one swivel type. Suitable locking lugs for fixing bowls to the machine. Because of all these qualities Planetary Mixer Manufacturers and Suppliers in India, leading as the best Planetary Mixer.

Top Dish: Stainless steel (SS) top dish designed to cover the bowl, featuring an SS flange with a groove for securing the sealing gasket. It includes a serrated nozzle for connecting a flexible pipe for vacuum applications and is equipped with light and sight glasses for visibility.

Agitator Assembly:

Drive Mechanism for Beater:

Lifting Arrangement of the Drive Assembly (Mechanical):

Main screw and guide bar to guide up and down traverse of the drive assembly.

Lifting Arrangement Hydraulic:

Control Panel:

Options Available:

Technical Specifications:

| Model No. | Gross Capacity | Working Capacity | Lifting Motor HP | Main Motor HP | RPM Planet / Beater | Space Required H x L x B |

|---|---|---|---|---|---|---|

| PCI PLM-30 | 30 | 20 Ltrs | – | 2 HP | 20-40 / 60-120 | 1220 x 640 x 520 |

| PCI PLM-65 | 65 | 50 Ltrs | – | 3 HP | 20-40 / 60-120 | 1500 x 900 x 600 |

| PCI PLM-125 | 125 | 100 Ltrs | – | 3 HP | 20-40 / 60-120 | 1650 x 1020 x 650 |

| PCI PLM-230 | 230 | 200 Ltrs | 1 HP | 5 HP | 18-36 / 54-108 | 2300 x 2100 x 1500 |

| PCI PLM-280 | 280 | 250 Ltrs | 1 HP | 7.5 HP | 18-36 / 54-108 | 3000 x 2900 x 1400 |

| PCI PLM-375 | 375 | 350 Ltrs | 1.5 HP | 10 HP | 12-24 / 36-72 | 2400 x 2300 x 1300 |

| PCI PLM-550 | 550 | 500 Ltrs | 2 HP | 15 HP | 12-24 / 36-72 | 2700 x 2600 x 1250 |

| PCI PLM-675 | 675 | 600 Ltrs | 2 HP | 15 HP | 12-24 / 36-72 | 3000 x 2800 x 1300 |

| CAPACITY 10 Liters to 10000 Liters | ||||||

© Copyright 2024 PharmaChem Cosmetics Industries. All Rights Reserved. Website Designed & Promoted by Web Vyapar India.