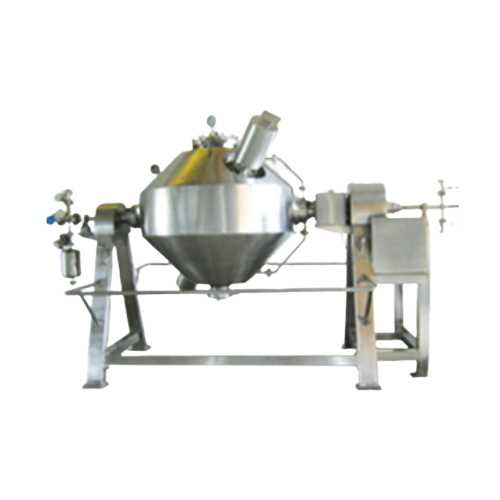

Pharmachem Cosmetics Industries is the top prominent manufacturing industry Rotocon Vacuum Dryer manufacturer in Mumbai for best drying machines. So, Retocon Vacuum Dryer or Dual Cone Vacuum Dryer is perfect for drying materials like water/solvents from wet powder collected after filtration units because these materials are not capable of protecting high-temperature levels and materials that are harmful and strong matches.

These are also valuable in averting oxidized and volatile materials that claim to be regained. Rotoocon Vacuum Dryer Suppliers in Maharashtra designed their product by using advanced mechanisms So, the product runs on a high-tech mechanism and performs perfectly under vacuum. Further, it enhances the drying process, operates at optimum temperatures, and provides an economical solution with a comprehensive solvent recovery system.

That is why Rotocon Vacuum Dryer Manufacturers and Suppliers in India are renowned for their prominence in offering their best drying machines. We have pre-manufactured standard sizes for RCVD's are 100 Litres, 200 Litres, 300 Litres, 500 Litres, 750 Litres, 1000 Litres, 1500 Litres, 2000 Litres, 2500 Litres, 3000 Litres, and 5000 Litters. We also supply Pilot Plants RCVD of at least 50 Liters or more capability.

Amazing Features -

• Inner shell/Cone and contact parts with SS 316.

• Steam/HW water Jacket has SS 304.

• Insulation with jacket has SS 304.

• Cyclone separator has SS 316.

• Condenser (shell & tube) and Receiver has SS304

• Butterfly valve (SS316) at performing port with dummy and hand wheel.

• Stand and Structure have SS 304/MS with SS304 cladding.

• Drive unit surrounded with SS304 Covers

• Dry Mechanical Seal with vacuum side.

• Dry Mechanical Seal with Waterside.

• FLP Motor & FLP Control panel shut in SS304 panel

• Digital Temperature Indicators (FLP) around Hot Water inlet and outlet.

• Digital Temperature Indicator (FLP) and Dial Vacuum measure in vapor line.

• Digital Temperature Controller (FLP) along with Pneumatic Valve at Hot water inlet.

• Provision for Nitrogen purging/Vacuum release isolation valve with interlocking

• Temperature and Vacuum Gauges (Dial Type) at Cone.

• Safety Guard/railing telescopic type has a limit switch (FLP) with interlocking.

• Drain plug and safety valve on HW/Steam Jacket.

• Pulse jet type dust filter is provided inner in the cone.

• Positioning wheel /inching button for cone

• DRIVE: Gear Box & Motor Direct together and Gear Box to Cone Drive shaft Bull Gear-Pinion Gear Drive.

• Extended shaft (drive side) hence unit can be kept in the service zone (if required)

• The Cone has wet material from the vacuum loading system

• FINISH: Outer 180 Grit Mat Finish Internal 320 Grit Mirror Polish.

Technical Specifications

| Model | PCI RCVD 100 | PCI RCVD 200 | PCI RCVD 300 | PCI RCVD 500 | PCI RCVD 750 | PCI RCVD 1000 | PCI RCVD 1500 | PCI RCVD 2000 | PCI RCVD 2500 | PCI RCVD 3000 | PCI RCVD 5000 |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Total Volume (Ltr.) | 100 | 200 | 300 | 500 | 750 | 1000 | 1500 | 2000 | 2500 | 3000 | 5000 |

| Working Volume (Ltr.) | 60 | 120 | 180 | 300 | 450 | 600 | 900 | 1200 | 1500 | 1800 | 3000 |

| Heat Transfer Area (m2) Approx | 3.5 | 4.5 | 5 | 6 | 7 | 8 | 9.5 | 11 | 12.5 | 14 | 20 |

| Cyclone Separator (Ltr.) | 5 | 7 | 10 | 15 | 20 | 25 | 30 | 40 | 50 | 60 | 75 |

| Condenser (m2) | 0.5 | 0.75 | 1 | 1.5 | 2 | 2.5 | 3 | 4 | 4.5 | 5 | 6 |

| Receivers (Ltr.) | 20 | 40 | 50 | 75 | 100 | 150 | 200 | 250 | 300 | 350 | 500 |

| Charging Size (mm) | 0150 | 0250 | 0300 | 0400 | 0400 | 0400 | 0400 | 0450 | 0450 | 0450 | 0500 |

| Discharging Size (mm) | 0100 | 0125 | 0150 | 0150 | 0175 | 0200 | 0200 | 0250 | 0250 | 0250 | 0300 |

| Main Motor (HP) | 2 HP | 3 HP | 3 HP | 5 HP | 5 HP | 7.5 HP | 10 HP | 10 HP | 12.5 HP | 15 HP | 20 HP |

© Copyright 2024 PharmaChem Cosmetics Industries. All Rights Reserved. Website Designed & Promoted by Web Vyapar India.