At Pharmachem Cosmetics Industries, we offer excellent quality filling machinery for a range of filling processes. Our product portfolio includes viscous fluid filling machines as well as those used to fill bottles and vials.

From Liquid Filling Machine Manufacturers in Mumbai, the Liquid Filling Machine is a versatile device widely employed in various industries to dispense raw materials into containers and package them to produce the final product. Numerous packaging companies have found value in this machine. In the liquid filler, the tanks, containers, or vessels follow a cycle: they are loaded by the machine and then prepared for packaging.

A liquid filling machine is designed by Liquid Filling Machine Suppliers in Maharashtra, to dispense raw liquid materials into containers and ampoules, subsequently transforming them into finished products that are displayed on shelves and available for purchase. There are various types of liquid filling machines worth mentioning.

Injectable Liquid vial filling machine – This is generally used to fill vials with medications. It activates on the volumetric concept, using diving nozzles and a pneumatic mechanism with rubber stoppers on the upper of the containers. The injectable fluid vial system structures a stainless steel flat conveyor belt that the vials portable and moves on. The vials are subsequently conveyed to the filling station, equipped with 2 to 12 heads. Following the precise filling, the following station places a closing of the head. The basic modules of the vial filling machine are a conveyor belt on which the bottles are transported and a filling and stoppering machine on which the vials are full and rubber stoppered so that no medical material is misused and precision is conserved.

Prefilled syringe filling machine– This equipment is ideally employed in the pharmaceutical sector, specifically for filling prefilled syringes. It features a stainless hopper for syringe storage, with a dedicated slot for pre-filled syringes located on top of the structure. Syringes are systematically conveyed to the filling station, where an automated pump is in place. Once filled to the appropriate quantity, the syringes move to an outfeed plate as part of the syringe filling process.

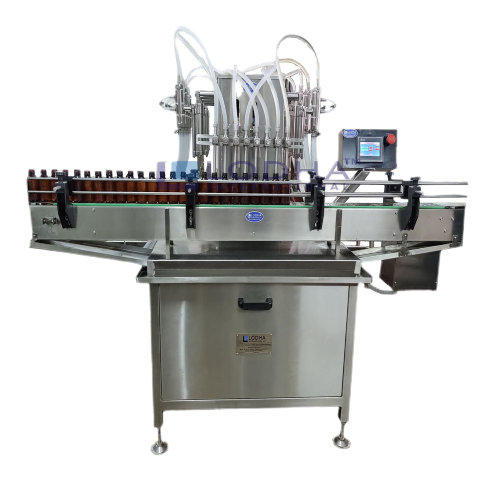

Liquid bottle filling machine– Bottles are loaded with a multiplicity of viscous liquids, like oil, which is utilized for both food and industrial properties. The volumetric or gravimetric technique can be used to fill containers. For loading the bottles, there is a funnel alternative. To convey force to denser fluids, pumps or pistons can be utilized if the fluid is thick or viscous. The liquid bottle-filling machine is employed for the precise dispensing of lotions and creams. The rapid nozzles facilitate a faster and more efficient discharge.

Linear Liquid filling machine– The lined fluid filling machine works on a volumetric basis and can fill up to 1000 ml bottles. The diving nozzle features a suck-back configuration and is used to avoid foam.

Oil filling machine–Automatic liquid filling devices, particularly those designed for high-speed operations, often incorporate various advancements. The oil filler equipment is a notable example, employing both line-to-line outward and inward filling techniques. Suitable for bulk production and packaging, this equipment efficiently fills oil into containers, bottles, and jars. The automated 8-head twin-track liquid filling with rubber stoppering machine boasts high speed and efficiency, featuring robust construction. Additionally, the Automated Rotary Piston Filling and Capping Machinery is a reliable choice, equipped with a rotary valve for drip-free filling. An AC frequency control system can be utilized to regulate the rotary's speed. Other in-demand equipment includes the Engine Oil Filler and Volumetric Oil Filling Machine, catering to both culinary and medicinal oil applications.

A liquid filling machine usually has the following features:

Liquid Filling Machine Manufacturers and Suppliers in India, are proud of their machines because they are adaptable, flexible, and waste-free. The machinery is made to fit the user’s needs and preferences, as well as the form and size of the receptacles they serve. A large industry means higher profits!

Process Of Liquid filling machine

The liquid filling machine's process begins with the initial step, involving the inline or horizontal type piston filler. This component directs and measures the fluid within the apparatus. Once the measurement and pouring steps of our vial filling machine are completed, the liquid output is promptly pumped into a vessel using a stainless filler with one or more heads. Despite the rapid nature of our liquid filling machine's process, the liquid within it remains secure and can be handled without any issues. Following the primary phase of our bottle-filling machine's operation, the secondary phase commences, allowing the equipment to fill a substantial number of containers per minute. Our liquid filling machine ensures a smooth, uninterrupted process. Upon the completion of all operations, the finalized product—filled bottles, containers, and vials—is collected. This comprehensive procedure delineates the functionality of our vial filling and packing technology

Salient Features:-

© Copyright 2024 PharmaChem Cosmetics Industries. All Rights Reserved. Website Designed & Promoted by Web Vyapar India.