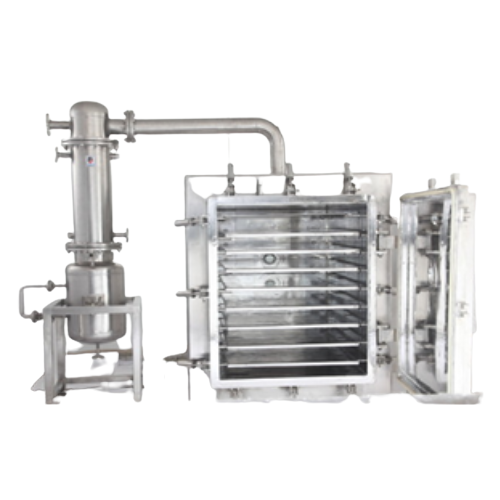

Pharmachem Cosmetics Industries is a prominent Vacuum Tray Dryer Manufacturers in Mumbai, specializing in the design of a Vacuum Tray Dryer that delivers excellent drying results in conventional processes. It has a double-walled cabinet with Single or Two doors. High-density fiberglass wool material is inserted between walls to prevent the transfer of heat. Doors are well furnished with gaskets. Stainless steel trays have four wheels that ensure easy movement.

The tray dryer is equipped with a control panel board, process timer, digital temperature controller cum indicator, and other features. Vacuum Tray DryerSuppliers in Maharashtra provide Vacuum Tray Dryer with capacities ranging from 6, 12, 24, 48, 96, and 192 trays. Electricity, hot water, steam, and hot oil are all available like heating media. Horizontal airflow affects the drying process. it enhances the drying process, operates at optimum temperatures, and provides an economical solution with a comprehensive solvent recovery system.

Vacuum Tray Dryer Manufacturers and Suppliers in India provide the chamber with a special design that secures a uniform air distribution and the least difference in temperature inside the chamber, providing the most efficient drying. PLC controller is used for the control system. The trays can be put directly on fixed tray supports inside the chamber or they can be stuck on mobile racks to be placed inside the chamber. Trays are provided with round corners for easy cleaning. You are free to join us via mail or call to enhance your whole process.

Amazing Features:-

• Digital Temp., symbol (FLP) at H.W. inlet & outlet

• Silicon transparent gasket for the door.

• Shelves Hollow Type pads SS316 with flow Baffles.

• Explosion Vent/Rupture Disc on vacuum chamber.

• Vacuum break valve impart on the vacuum chamber

• Condenser (Shell & tube) and Receiver in SS 304 with Isolation valve and Flow Glass in between to monitor precipitation.

• Provision for Validation Port on Body

• Drain valve for Vacuum chamber and Receiver.

• Heavy duty SS316 flange door SS 316 (hemisphere shape).

• Main Body/Vacuum chamber S Main Body/Vacuum chamber SS316 with heavy-duty SS316 flange and Stiffeners.

• Vacuum chamber provided nitrogen purging valve

• Trays (without back folding) have SS316 rounded corners and edges.

• Digital Temperature Controller (FLP) with solenoid controlled Pneumatic managed valve at Hot Water inlet.

• Dial type Vacuum compute and Digital Temp., Indicator (FLP) in Vapour line.

• Pressure discharge valve in Steam line.

• View Glass/Light glass available on vacuum chamber Door, Body, and Receiver.

OPTIONS :

• Heating Shelf unit portable system fitted on SS316 Trolley and SS304 external Trolley.

• Condenser and Receiver in SS 316 alternate of SS304.

• Vacuum chamber has Limpet coil

• The vacuum chamber's outer surface and door have insulation. The insulation is enclosed and covered with dispatchable SS 304 panels

• Skirting/Wall panel all forward to the body/vacuum chamber flange

• Tank (Insulated) has a hot water system (Steam heated), SS304 Steam Radiator/Electrical heaters, and Circulation pump with FLP Motor and controls.

Technical Specifications:-

| Model | PCI TD 3G | PCI TD 6G | PCI TD 12G | PCI TD 24G | PCI TD 36G | PCI TD 48G |

|---|---|---|---|---|---|---|

| No. Of Trays | 3 | 6 | 12 | 24 | 36 | 48 |

| Capacity in Kg | 3-5 | 12-18 | 25-35 | 50-75 | 75-100 | 100-150 |

| Tray volume in Ltrs /Capacity in Kg | 5/1-1.5 | 10/2-3 | 10/2-3 | 10/2-3 | 10/2-3 | 10/2-3 |

| Tray size : L W H in mm | 406x406x31 | 812x406x31 | 812x406x31 | 812x406x31 | 812x406x31 | 812x406x31 |

| No. of Heating Shelfs | 4 | 7 | 7 | 13 | 13 | 17 |

| Shelf size in mm | 430x430 | 430 X835 | 835x835 | 835x1259 | 835x1250 | 835x1250 |

| Distance between shelves in mm | 100 | 100 | 100 | 100 | 100 | 100 |

| Trays on each self | 1 | 1 | 2 | 2 | 3 | 3 |

| Condenser | 0.2m2 | 0.5m2 | 0.75m2 | 0.1m2 | 1.5m2 | 2m2 |

| Receiver | 10 Ltrs | 25 Ltrs | 50 Ltrs | 75 Ltrs | 100 Ltrs | 150 Ltrs |

| H.W. Distribution Pipes | 1½” | 1½” | 1½” | 1½” | 1½” | 1½” |

| Door Gasket (Silicon) | 16mmSQ | 16mmSQ | 16mmSQ | 16mmSQ | 16mmSQ | 16mmSQ |

| No. of Door Bolts (Φ40) | 4 | 6 | 8 | 10 | 12 | 12 |

| Design Temperature: 1500C, TESTING: The vacuum dryer shelves are hydro-tested 5 Kg/Cm2 in Assembled condition. The vacuum chamber is tested for full vacuum. | ||||||

| OVERALL DIMENSIONS (Approximately): | ||||||

| Width in mm | 900 | 1250 | 1700 | 1750 | 1800 | 1850 |

| Depth in mm | 900 | 1500 | 1500 | 1500 | 1900 | 1900 |

| Height in mm | 1100 | 1850 | 1900 | 2200 | 2200 | 2600 |

| Weight in mm | 400 | 700 | 1000 | 1500 | 2000 | 2500 |

© Copyright 2024 PharmaChem Cosmetics Industries. All Rights Reserved. Website Designed & Promoted by Web Vyapar India.