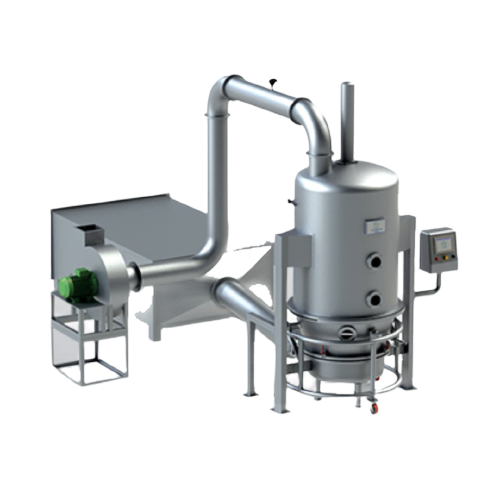

PHARMACHEM COSMETICS INDUSTRIES stands as the world’s premier industry of Fluid Bed Dryer Manufacturers in Mumbai. Our Fluid Bed Dryer is considered for fast and uniform dryings of powder, crystal, and medium-sized pellets. The Fluid Bed Dryers machine is utilized in various industries, including pharmaceuticals, Bulk Drugs, Dyes & chemicals, phytochemicals, Catalysts, Food Products and starch derivatives, Agro, Pesticides, and more.

Fluid Bed Dryer machines catch applications in pharmaceuticals, Bulk Drugs, Dyes and chemicals, Phyto-Chemical, catalysts, Food Products and starch derivatives, Agro, Bug killers, etc.

Fluid bed dryers are highly effective for drying granules, crystalline, coarse, or similar material in pharmaceuticals, fine chemicals, dyes, foodstuffs, and allied industries, offered by the best Fluid Bed Dryer Suppliers in Maharashtra.

Fluid bed processing involves drying, agglomeration, granulation, and varnishing of particulate materials. It is ideal for a varied range of both heat-sensitive and non-heat-sensitive products. Creating a fluidized state involves passing hot air through a product layer under controlled velocity conditions, ensuring uniform processing conditions.

Using intimate air-to-product contact, Drying is carried out by heated air delivered as the main source for drying, as it is effectively introduced by steam heating which gives high rates of heat exchange at high thermal efficiency while avoiding overheating of individual particles.

The process of coating powders, granules, or tablets in a fluid bed includes spraying a liquid onto the fluidized powder under precisely controlled conditions. It is the ideal equipment for Fluid Bed Dryer Manufacturers and Suppliers in India aligning with the requirement of cGMP.

The wet material is filled into the product container which is provided with an air purveyor plate and Dutch weave mesh. The fresh air in contact with the product undergoes a 3-way filtration process, passing through a coarse filter, 5-micron filters, and a heated HEPA filter using a heater (steam or electrical). This hot air then permits through the product container, generating turbulence in the product, and hence product moves up and down in the product container. Due to this, the heat transfer is rapid and the product is dried fast without significant heat loss. The filter bag prevents particles from escaping the dryer.

APPLICATION:-

• Appropriate for drying humidity from powder raw material in Pharmaceutical, foodstuff, feed, chemical industries, etc.

• Semi-liquid materials, large granules, small blocks, and adhesive substantial.

• The material volumes differ during the drying process.

• Option available for either Steam-Heated or Electric Heated Blower.

• Fluid bed Dryer can be supplied with Upgradation to be used as a workstation (Vertical Spray Granulation)

• Pharmaceutical granules or crystals comprising free moisture can be easily dried as per customer’s requirement.

• Versatile Process Equipment ensuring Uniform and Efficient Drying of Products.

• Option available for CGMP Model with Documentation (IQ, DQ, PQ, OQ)

• Minimum Supervision and More Hygienic.

• Product Container features a Lifting and tilting device for convenient Handling.

• Capacity Offered from 5 Kgs to 500 Kgs.

• FLP Models Available as Option.

• MOC S.S. 304/ 316/ 316L.

Fluidized Bed Dryer are used in numerous different broads applications and activities for foods, feeds, fertilizers, pharmaceuticals, and plastics industries.

Fluid bed dryers have a Capacity of Kgs that are-

• 5 KGS FLUID BED DRYER

• 10 KGS FLUID BED DRYER

• 30 KGS FLUID BED DRYER

• 60 KGS FLUID BED DRYER

• 100 KGS FLUID BED DRYER

• 120 KGS FLUID BED DRYER

• 150 KGS FLUID BED DRYER

• 200 KGS FLUID BED DRYER

• 250 KGS FLUID BED DRYER

• 300 KGS FLUID BED DRYER

• 350 KGS FLUID BED DRYER

• 500 KGS FLUID BED DRYER

• 600 KGS FLUID BED DRYER

• 1000 KGS FLUID BED DRYER

• FLUIDIZED BED DRYER

• FBD

Technical Specifications

| Model | PCI FBD-15 Kg | PCI FBD-30 Kg | PCI FBD-60 Kg | PCI FBD-120 Kg | PCI FBD-200 Kg | PCI FBD-250 Kg | PCI FBD-300 Kg | PCI FBD-500 Kg |

|---|---|---|---|---|---|---|---|---|

| Container Volume: Litres | 18 | 100 | 200 | 380 | 650 | 800 | 980 | 1700 |

| Batch Capacity : in Kg | 5-8 | 30-40 | 60-75 | 120-140 | 200-225 | 250-280 | 300-300 | 500-500 |

| Drying Temp C | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

| Motor H.P. | 3 | 5 | 10 | 15 | 20 | 25 | 30 | 60 |

| Heating Load: KW for Electrical Heating Approximately Steam | 9 | 18 | 54 | Electrical Heating is not recommended. | ||||

| Consumption Kgs./hr at Steam pressure 3 Kg/cm2 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 | 50-80 |

| Consumption Kgs./hr at Steam pressure 3 Kg/cm2 | 15 | 25 | 50 | 100 | 160 | 200 | 250 | 430 |

| Capacity Start From 2 kg To 1000 kg | ||||||||

© Copyright 2024 PharmaChem Cosmetics Industries. All Rights Reserved. Website Designed & Promoted by Web Vyapar India.